Bright, Energy Efficient COB LED Displays | Video Walls | Screens

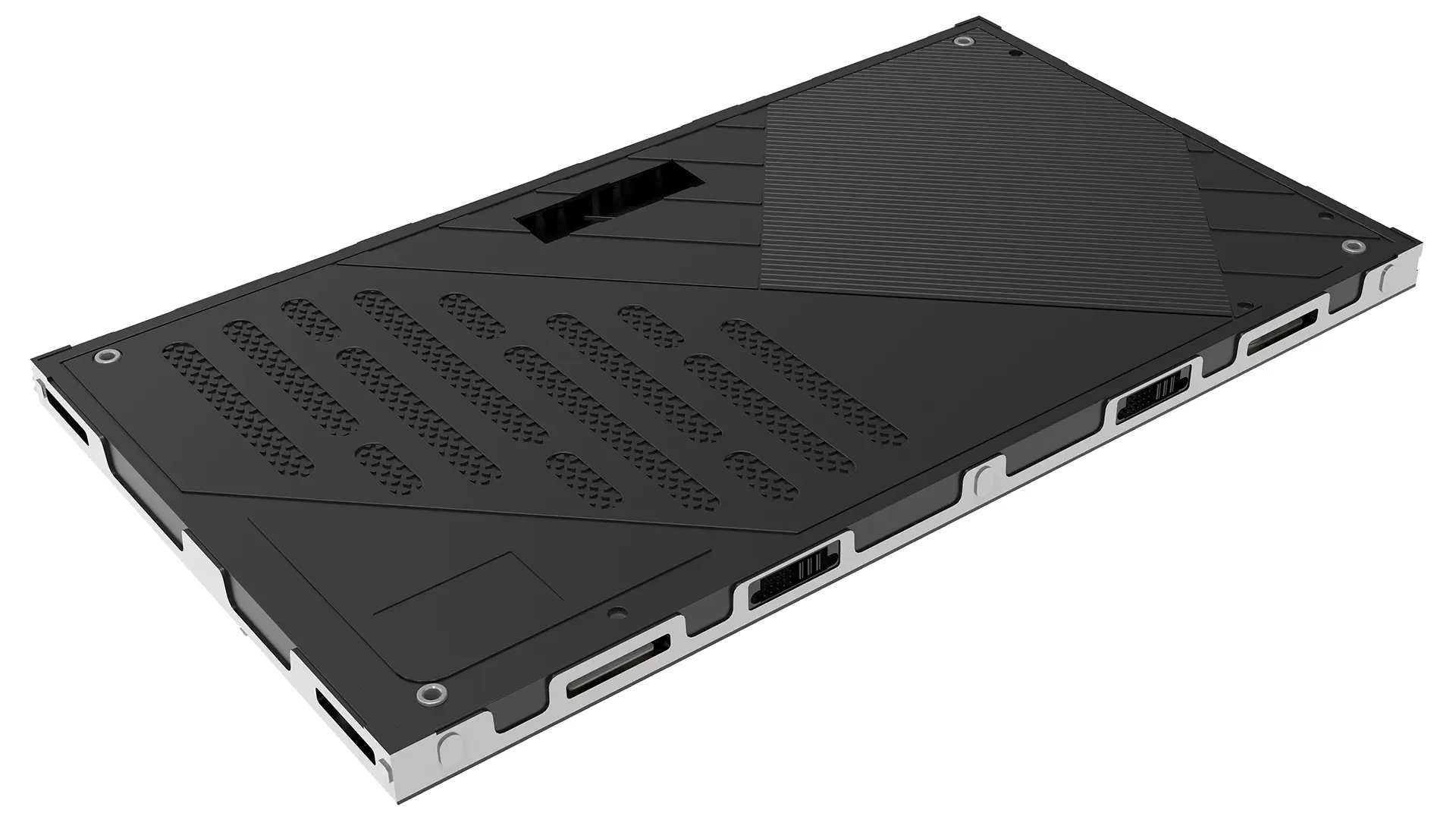

Answer-01: The Chip-on-Board (COB) technology utilized in LED displays entails the direct mounting of multiple LED chips onto a substrate, resulting in a densely packed array of light sources. This approach facilitates enhanced thermal management and increased lumen output when compared to conventional LED packaging methods.

Answer-02: COB indoor LED displays offer advantages such as enhanced thermal management, higher pixel density, improved reliability, better color uniformity, reduced glare and improved visual comfort. They also provide high resolution, excellent color consistency, wider viewing angles and enhanced reliability. Additionally, they feature seamless display surfaces and superior heat dissipation capabilities. Moreover, COB indoor LED displays offer higher brightness levels, improved heat dissipation efficiency, enhanced color uniformity and wider viewing angles. Furthermore, they tend to have a longer lifespan and can be more cost-effective in certain applications.

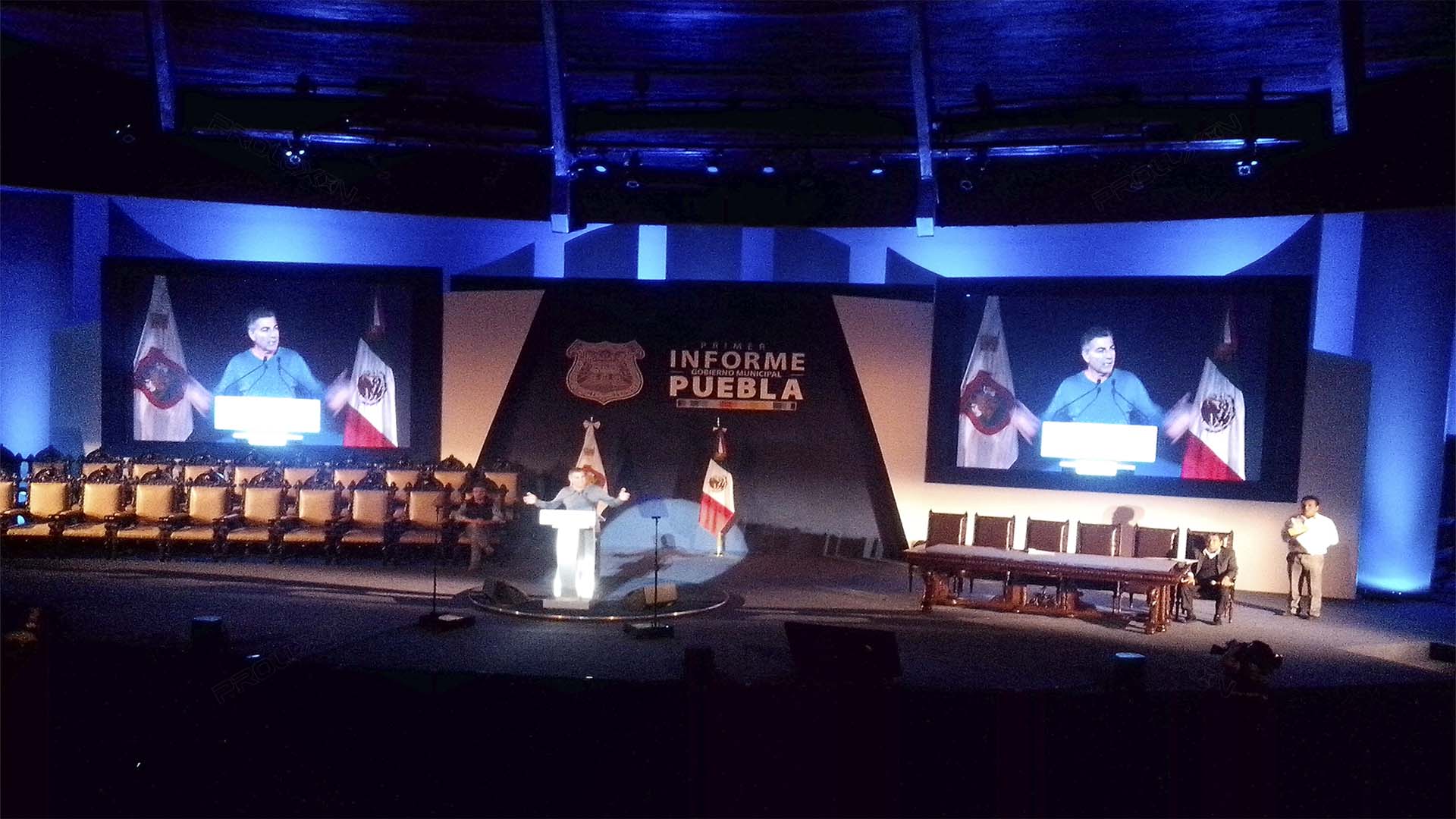

Answer-03: The COB indoor LED displays are widely utilized in various applications, including indoor advertising, retail signage, sports arenas, conference centers, and control rooms. Their exceptional brightness and color uniformity make them highly suitable for diverse indoor environments where visual impact is of utmost importance. Typical implementations of COB indoor LED displays encompass advertising campaigns, retail showcases, stage performances in enclosed spaces, conference facilities, control rooms as well as a wide range of indoor events that necessitate high-resolution and high-brightness display solutions.

Answer-04: COB indoor LED displays generally offer superior heat dissipation, enhanced brightness, improved color uniformity, and a wider viewing angle compared to other types of indoor LED displays. Moreover, they can provide a more seamless and high-resolution visual experience. In contrast to traditional SMD (Surface Mount Device) LED displays, COB technology offers superior color uniformity, higher pixel density, and enhanced reliability. It also ensures a more seamless display surface.

Answer-05: The maintenance of COB indoor LED displays typically involves regular cleaning to remove dust and dirt, inspecting for any dead pixels or anomalies, and ensuring proper ventilation for heat dissipation. Additionally, it is crucial to monitor the power supply and connections for any signs of wear or damage. Regular cleaning and inspection for loose connections or damaged components are recommended. However, due to its robust design, COB technology generally requires minimal maintenance.

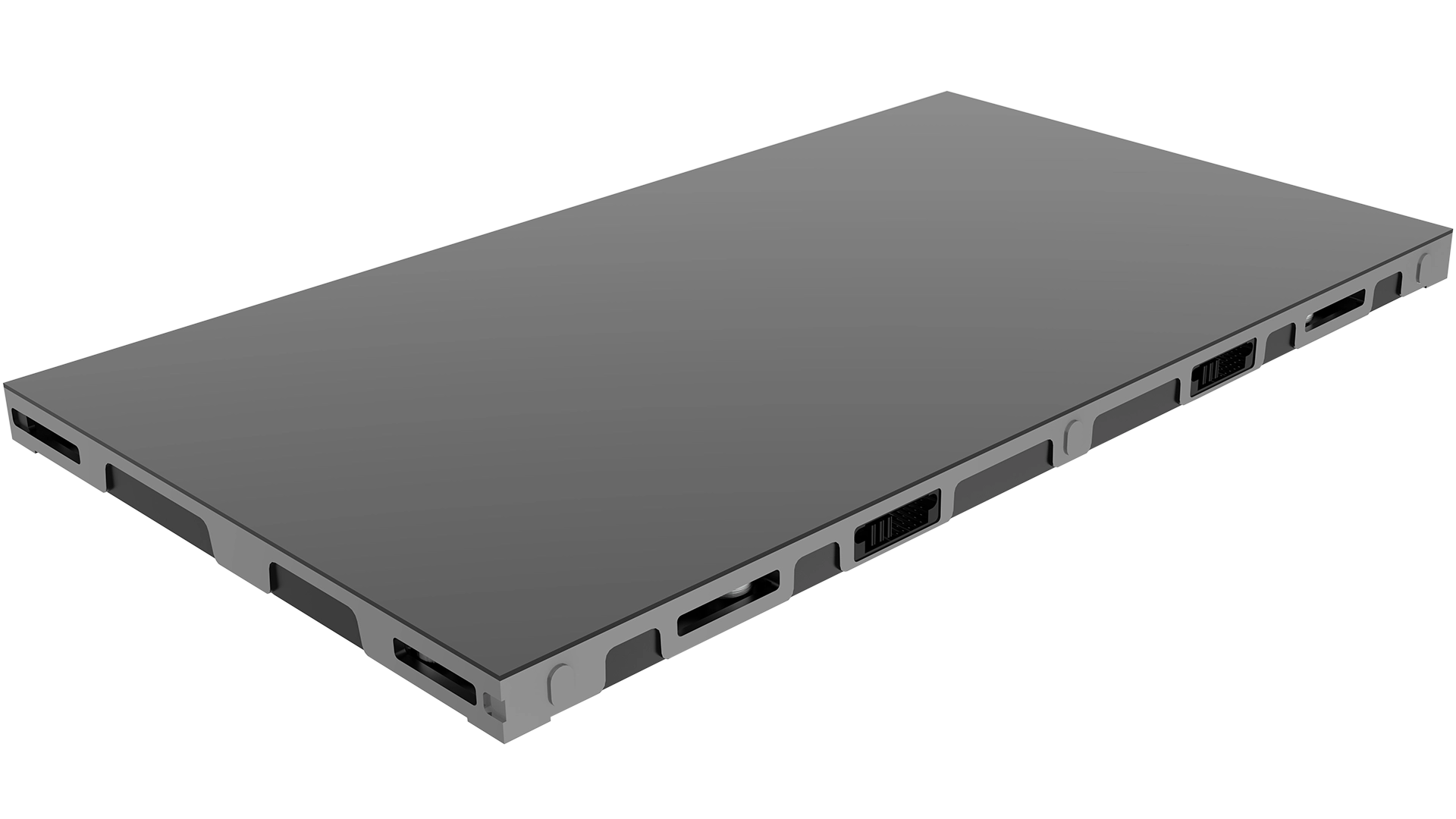

Answer-06: The MIP technology offers numerous advantages, including efficient light mixing, high uniformity, absence of Mura effect, low-cost repairs and direct testing and sorting capabilities. It also exhibits unique compatibility with large-scale mass production of large-size Micro LEDs and is widely accepted by terminal display manufacturers. In scenarios involving smaller spacing and larger sizes for terminal displays, MIP effectively overcomes core bottlenecks related to yield, ink color consistency, uniformity inspection and repair costs. Consequently, it emerges as an ideal choice for Micro LED display production. Furthermore, apart from its technical benefits, MIP aligns with the original process of LED displays in terms of manufacturing process and technology aspects. This implies that MIP boasts higher compatibility across various manufacturing processes. Comparatively speaking between MIP and COB technologies: COB can only encapsulate LED chips with a bilateral size greater than 100μm whereas MIP can encapsulate LED chip sizes below 60um; at the display level itself - point spacing is smallest for MIP followed by COB. Overall analysis suggests that when considering factors such as LED chip size requirements electrical connection contrast mounting process repairability flatness mixed light bins etc.,MIP outperforms COB.