Technology Sharing For Relelation of Mini LED and Micro LED Driver Technology

The pixel density of LED display products is continuously increasing, leading to the expansion of application boundaries and a growing demand for high image quality. In recent years, Mini/Micro LED has emerged as a prominent term in the display industry, being hailed as the next generation display technology. Major manufacturers have significantly increased their investment in research on Mini/Micro LED technology and are actively developing corresponding display products.

The LED display industry has been developing in China for over 30 years, with the development of indoor small-pitch products spanning more than a decade. So what sets Mini/Micro LED apart from previous small-pitch LED displays? From an application standpoint, Mini/Micro LED display products utilize smaller luminous bodies compared to conventional small-pitch LED displays. This translates to higher resolution per unit area, which has already had a profound impact on the entire industry chain (including drive solutions, substrates, transfer equipment, etc.) and has propelled the overall industry towards advanced display technologies and products. Consequently, it is poised to significantly expand the scope of LED display applications. There are three primary areas of application:

1. Large-size display applications. Micro LED exhibits immense development potential and is progressively penetrating outdoor ultra-high-definition display applications, encompassing outdoor high-definition large screens, upscale exhibition displays, top-tier conferences, and large-scale Micro LED TVs. This will significantly enhance the quality of conventional large-size LED displays.

2. Medium-sized consumer applications will gradually adopt Micro LED as it replaces LCD, positioning itself as the next generation of advanced display technology after OLED. This innovative technology is expected to be utilized in various devices such as wearables, PC monitors, and high-end TVs.

3. Small-sized micro display applications, such as augmented reality (AR), virtual reality (VR), and mixed reality (MR), are expected to witness significant growth with the continuous development and maturation of Micro LED technology. As this technology enters the era of large displays, it is anticipated that the capacity of the LED display market will reach trillions.

Although the future appears promising, it is crucial not to underestimate the challenges posed by technology and product development. Firstly, Micro LED chips are incredibly small in size. To achieve large-scale mass production and commercialization successfully, collaboration between upstream and downstream industries is imperative. Secondly, in terms of large-size display applications, Micro LED predominantly utilizes PCB substrates. While the process technology for PCB substrates is mature and capable of mass production and commercial use, it fails to meet the demands of small and medium-sized display applications due to significant increases in pixel density that result in inadequate line width and warpage accuracy. Currently, there is active development of glass substrates within the industry with some samples on display; however, they have yet to reach a stage of mature large-scale mass production and commercial utilization primarily due to technological limitations as well as cost constraints.

In addition to the aforementioned aspects, driving technology plays a pivotal role in enabling the widespread application of Micro LED in small and medium-sized displays. Presently, conventional LED small-pitch driving solutions fail to meet the high-resolution requirements of Micro LED for such applications. Currently, there are three primary driver solutions employed in Mini/Micro LED display products. Let's delve into them.

PM Driver

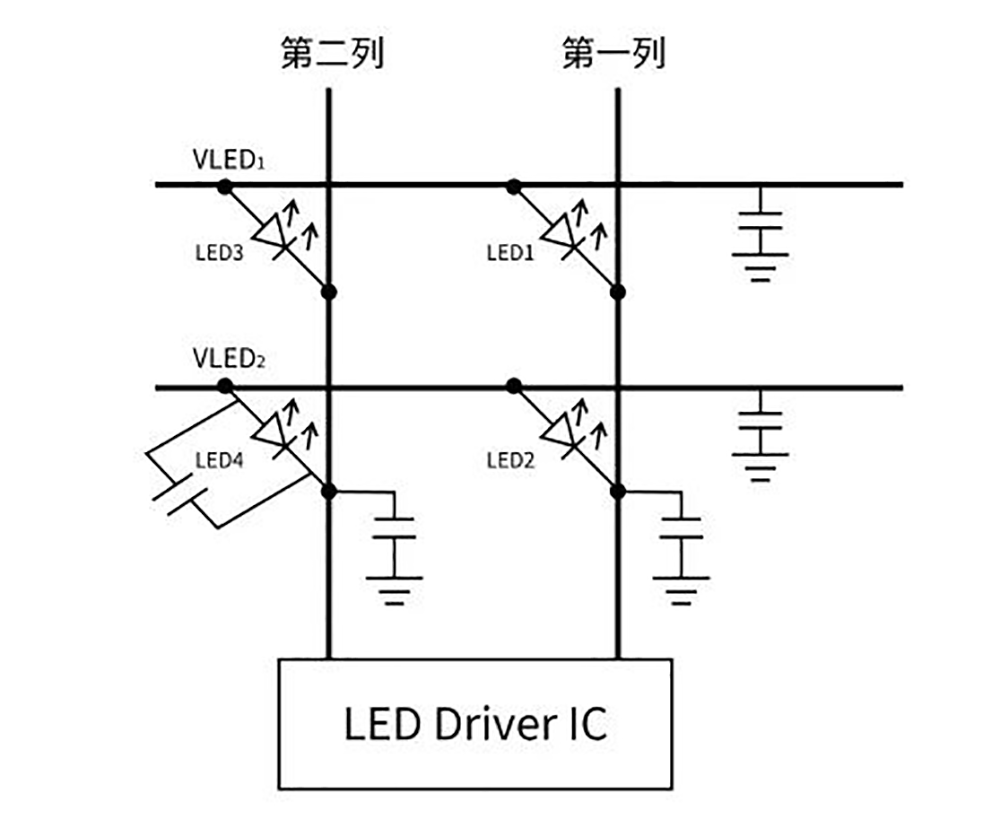

The PM driver connects the anode (P-electrode) of each column of LEDs in the LED display array to the column scan line (Data Current Source), and simultaneously connects the cathode (N-electrode) of each row of LEDs to the row scan line (Scan Line). This configuration ensures superior performance. When a specific Y-th column scan line and X-th row scan line are activated, the LEDs at their intersections (X, Y) will be illuminated. The entire LED screen is rapidly scanned and lit point by point using this method, effectively eliminating visual persistence experienced by human eyes. Ultimately, this enables realization of a fully functional display screen.

The implementation of this PM point-by-point scanning method is relatively straightforward, but it results in a more complex PCB design and wiring process. Additionally, the LED undergoes cyclic scanning at a high speed with very short lighting time, leading to low brightness efficiency. Furthermore, the extensive use of scanning circuits and resistive components introduces noticeable crosstalk between LED pixels and imposes high frequency requirements on scanning signals. Consequently, these challenges pose limitations on driving technology and hinder the application of Micro LED in small and medium-sized high-resolution screens.

The pixel density of Mini/Micro LED display products has been significantly enhanced compared to traditional small-pitch products, with a notable increase in the number of LED light-emitting devices. How can the control of these additional LED light-emitting devices be effectively managed? Currently, most solutions employ large-scan, multi-channel highly integrated driver ICs to address this challenge. For instance, scanning methods range from 16 scans to 32 scans, 64 scans or even 96 scans. However, simply increasing the number of scans may not suffice due to limited space on the substrate for accommodating numerous driver ICs. Consequently, more than 16-channel driver ICs are being introduced successively to support the industry in manufacturing higher-definition LED display products.

Currently, the existing PM high-scan and multi-channel small-pitch LED driving solutions still fail to effectively address issues such as dim brightness, low gray uniformity, and coupling under high contrast. These problems primarily stem from the influence of parasitic capacitance. During PCB design, adjustments in circuit layout can be implemented to minimize parasitic capacitance. Moreover, with decreasing pixel spacing and increasing PCB line density, the impact of parasitic capacitance becomes more pronounced. Therefore, it is crucial to carefully consider driver solutions while not neglecting PCB design.

AM Driver

The AM driving method has been extensively studied in conjunction with the emergence of Micro LED technology, as it enables the production of high PPI display products that cannot be easily achieved through PM driving. Currently, it is being experimented with in COG applications. In comparison to PM drive, AM drive can be likened to an EMU train where each carriage possesses its own power source, allowing for higher brightness utilization of Micro LED. On the other hand, PM drive resembles a green train where only the front compartment has power and transmits power to subsequent compartments similar to point-by-point scanning and lighting in PM technology. However, due to the high-speed cycling of LEDs in PM-driven screens, their brightness efficiency is low and displayed images are often inconsistent and unstable. Consequently, this makes small and medium-sized Micro LEDs unsuitable for consumer market applications.

The advantages of AM can be summarized as follows: it enables the realization of Micro LED display products with higher PPI, achieves enhanced brightness and lower power consumption, ensures uniform brightness and higher contrast, and provides a more stable image display. It is foreseeable that in the future, AM will emerge as an improved driver solution for mass production and commercialization of small to medium-sized Micro LED devices.

"Semi-active" Driver

Semi-active driving employs a single transistor as the driving circuit for Micro LED pixels, effectively preventing crosstalk between pixels. This solution serves as an intermediate option between PM and AM, harnessing the advantages of both technologies. Although currently underutilized in LED displays, with ongoing research on commercial applications of Micro LED in the industry, semi-active drives may gain more traction in the future.

The above thoughts pertain to the current applications of Mini/Micro LED displays, as well as the three commonly employed drive solutions and the advantages and disadvantages of Micro LED technology. The industry will focus on large, medium, and small-sized applications based on technological maturity, mass production capabilities, and pricing considerations. When selecting an application, it is important to consider the rapid development of Mini/Micro LED display technology and products. Higher definition, improved image quality, and reduced energy consumption are emerging trends in ultra-high definition displays. We anticipate that AM drivers may play a significant role in future Mini/Micro LED displays. This represents a key direction for driving technology in small and medium-sized displays.

Links: COB Display | MIP Display | Indoor Display | LED Display Videos